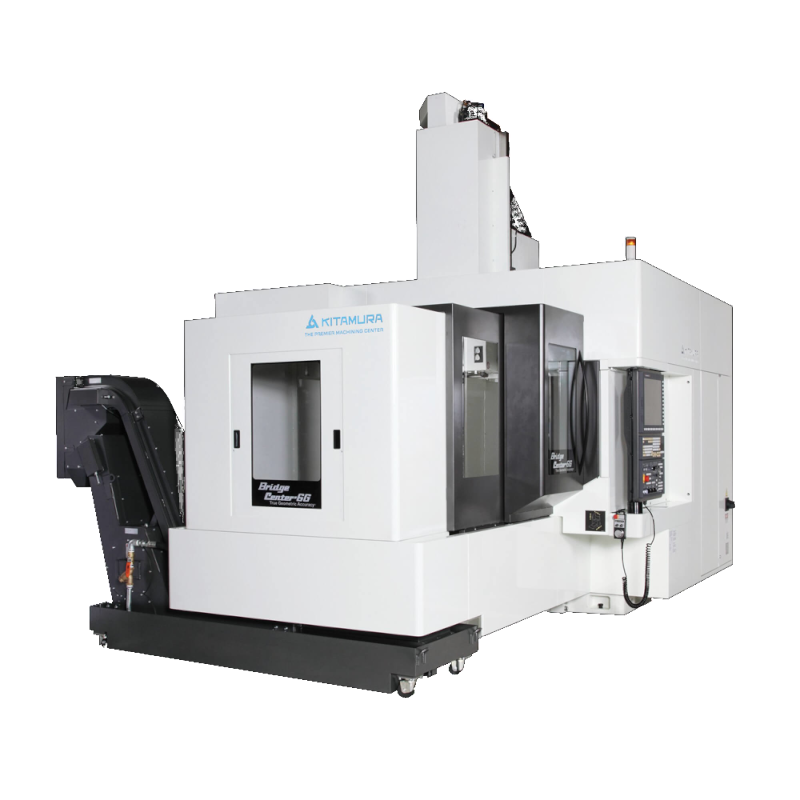

Bridgecenter-6G (40 & 50 Taper)

Kitamura Bridgecenter-6G (40 & 50 Taper)

DOUBLE COLUMN MACHINING CENTER

Specifications

|

Table Size:

|

|

|

Travel (X, Y, Z):

|

|

|

Spindle Taper:

|

|

|

Spindle Speed:

|

|

|

Tool Storage Capacity:

|

|

|

Tool Change Time (T-T/C-C):

|

|

|

Rapid Feed (X, Y, Z):

|

|

|

Power Requirement:

|

Features

- Ideal for parts requiring heavier cutting loads and higher levels of precision and accuracy. Excellent for Die/Mold applications.

- Positioning Accuracy: ±0.000078”/Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #40, high speed, heavy duty 20,000rpm, 4-Step Geared, Dual Contact Spindle

- Double column design provides expansive work envelope and superior rigidity

- Linear scale feedback in X, Y, Z axes

- Space saving footprint takes up only 166 total square feet

- 6,600Lb table capacity