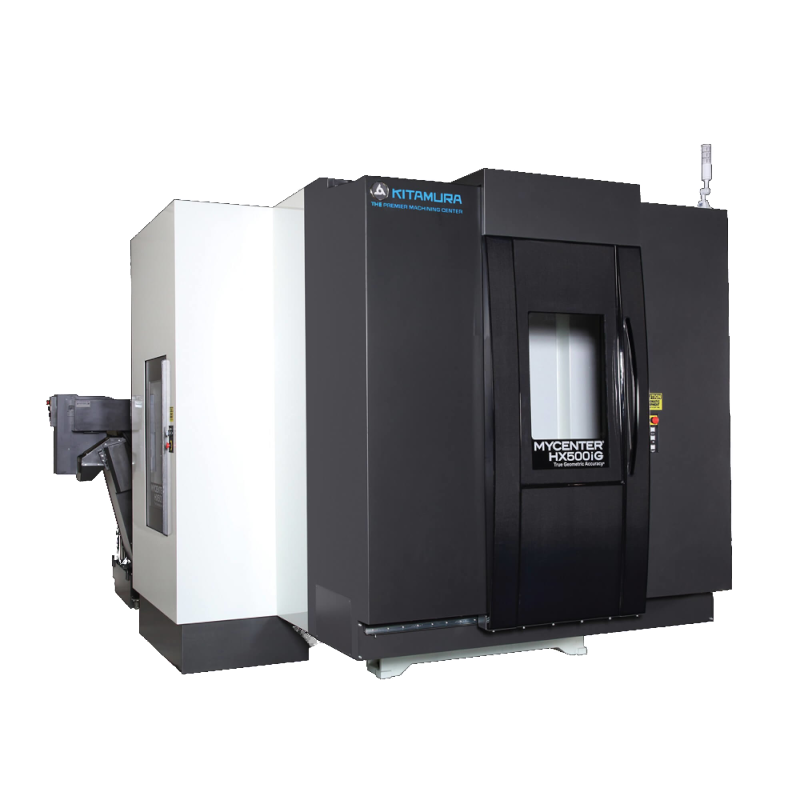

Mycenter HX‐1000G

Kitamura Mycenter-HX1000G

HORIZONTAL MACHINING CENTER

Specifications

|

Table Size:

|

|

|

Travel (X, Y, Z):

|

|

|

Spindle Taper:

|

|

|

Spindle Speed:

|

|

|

|

|

|

Tool Storage Capacity:

|

|

|

Tool Change Time (T-T/C-C):

|

|

|

Rapid Feed (X,Y,Z)

|

|

|

Power Requirement:

|

Features

- Solid box way design combined with the rigidity of high grade meehanite casting

- Positioning accuracy: ±0.000078”/full stroke, Repeatability: ±0.000039”

- Linear scale feedback on X, Y, Z axes

- Full 4th axis rotary table with high resolution scale

- Maximum workpiece size 80.71” dia x 61.02” height. Table load capacity of 6,600Lbs +

- Patented twin ballscrew/twin servo motor driven axis drive system

- Flexibility with the ability to add a 5th axis in the field