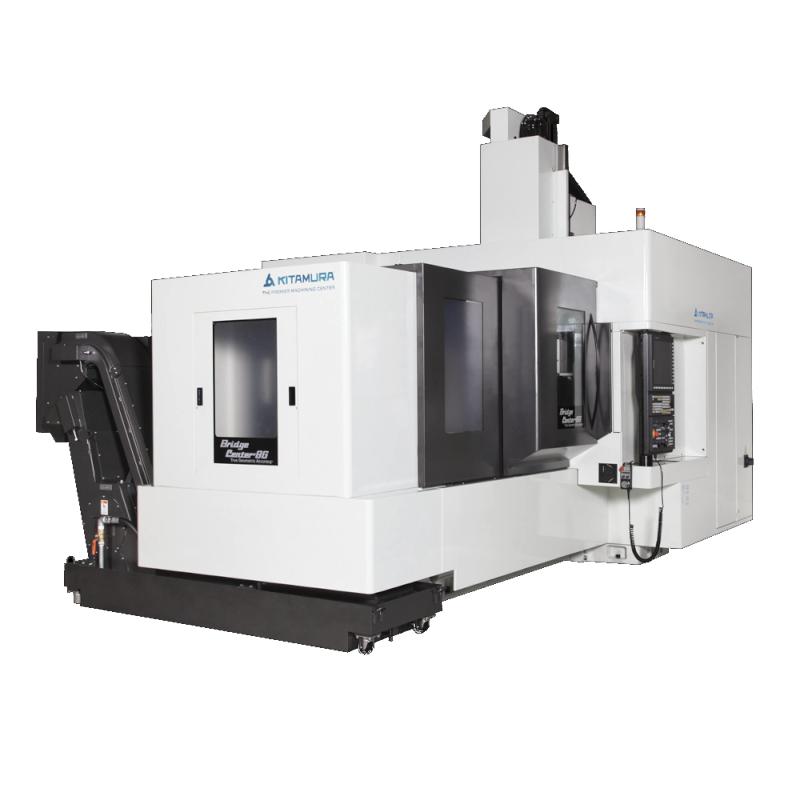

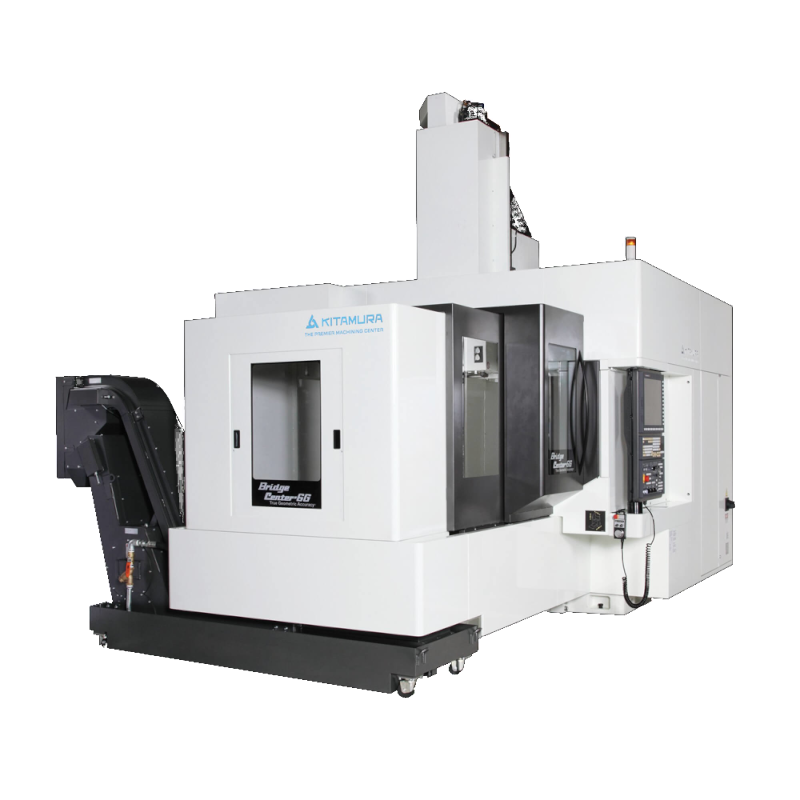

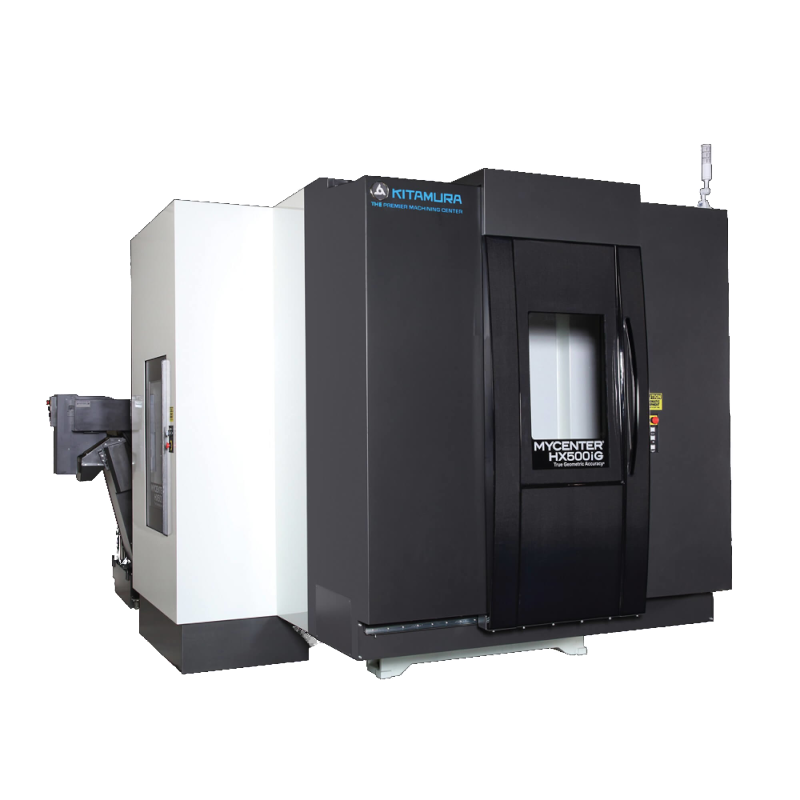

Bridgecenter-8G

Kitamura Bridgecenter-8G

|

Table Size:

|

|

|

Travel (X, Y, Z):

|

|

|

Spindle Taper:

|

|

|

Spindle Speed:

|

|

|

Tool Storage Capacity:

|

|

|

Tool Change Time (T-T/C-C):

|

|

|

Rapid Feed (X, Y, Z):

|

|

|

Power Requirement:

|

- Ideal for parts requiring heavier cutting loads, and parts that require a higher level of precision and accuracy.

Excellent for Die/Mold applications. - Positioning Accuracy: ±0.000078”/Full Stroke, Repeatability: ±0.000039”

- Rigid Meehanite cast iron construction with induction hardened solid box ways

- #50, High Speed, High torque 12,000rpm, Dual Contact, 4-Step Gear Driven Spindle

- Double column design with patented triangular crossbeam provides expansive work envelope and superior rigidity when compared with C-Frame style machines

- Linear scale feedback in X, Y, Z axes

- Space saving and compact, the Bridgecenter-8G measures only 137.6″ x 230.9″ (3,494 x 5,866mm) on your floor!

- 7,700 Lb table capacity allows for the capacity to machine larger and heavier work pieces